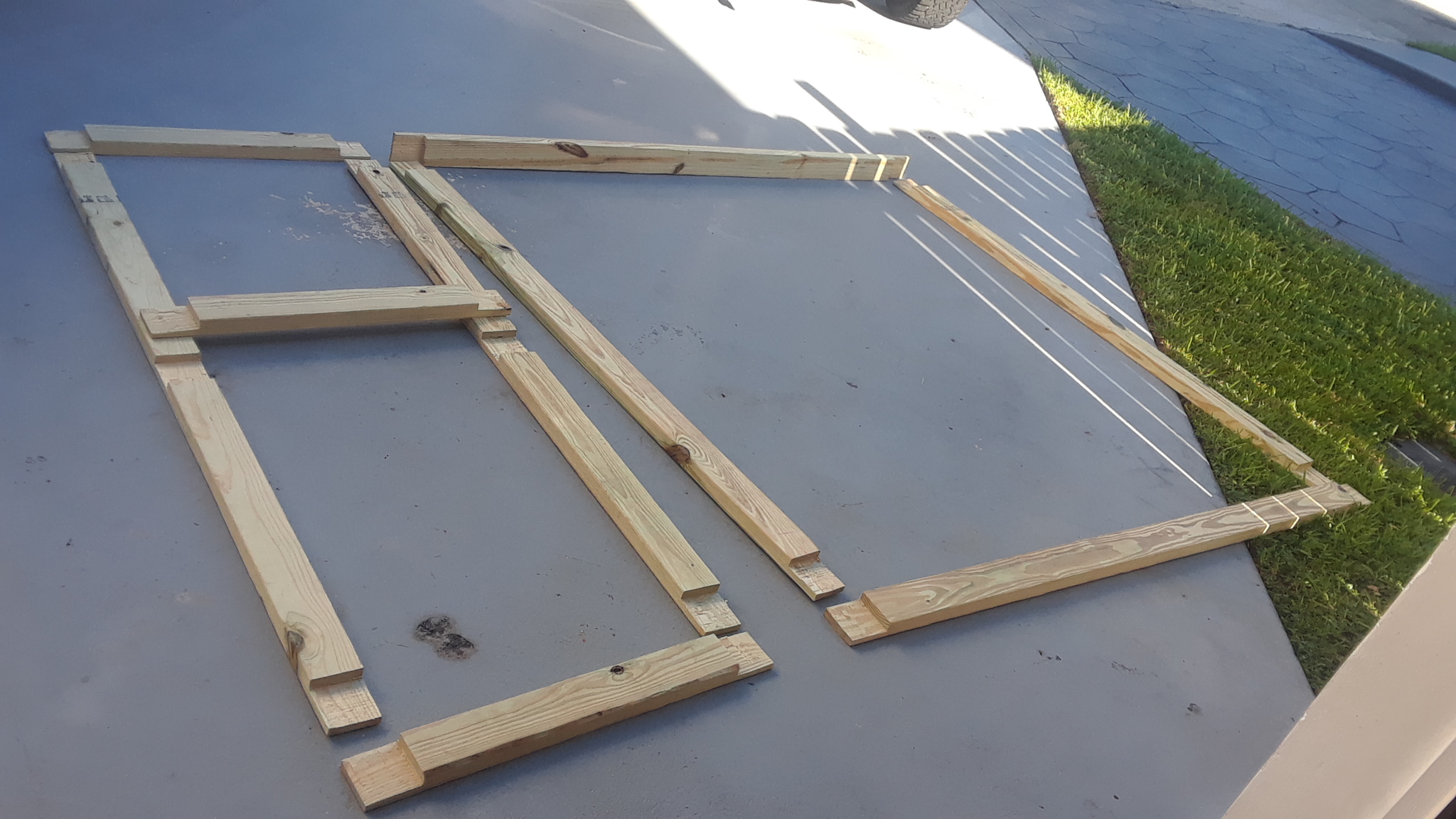

My gate rebuild was long overdue, I wanted to build a double swing gate, large enough for my trailer to exit, with a smaller more accessible side entrance for regular use

Laid out and cut the half lap joints for both gates

I used a horizontal deck board spanning the bottom of the gate. My reasoning for this is to raise the gate creating more privacy and the thickness of this type of board will hold up better to the damage caused by the weed trimmer which caused my last gate boards to rot prematurely. If there is damage to this board, I can simply unscrew and replace it if needed.

Takeaways: If I were to do this again, I would make the following changes

I reused the gate hinge hardware, which I should have replaced with a differently style of hinge, which would open fully and flush. Because of this style of hinge, I was left with a large gap, which is needed for the gate to open fully. I spent a lot of time trimming an notching the end boards, to allow for the necessary clearance, then adding an overlapping board on hinges and magnets to close fully.

I did not take into consideration the length of running the X brace on the large gate, would exceed the length of the 2×4’s which I purchased for this build. Because they were a few inches short, I needed to brace the corners with 3 little triangle pieces, pocket hole screwed together, to create the proper brace.

I used a round over bit to route all of the gate boards. In doing so, I created more of a gap between boards, even when clamped in place as the ends of the boards were not all straight. Next time I would have set up the table saw to cut a 45* bevel on opposing sides of the boards to fit together and overlap to create more of a seamless look.